The Importance of Cleaning Injection Molding Machines with Purging Compounds for Plastic

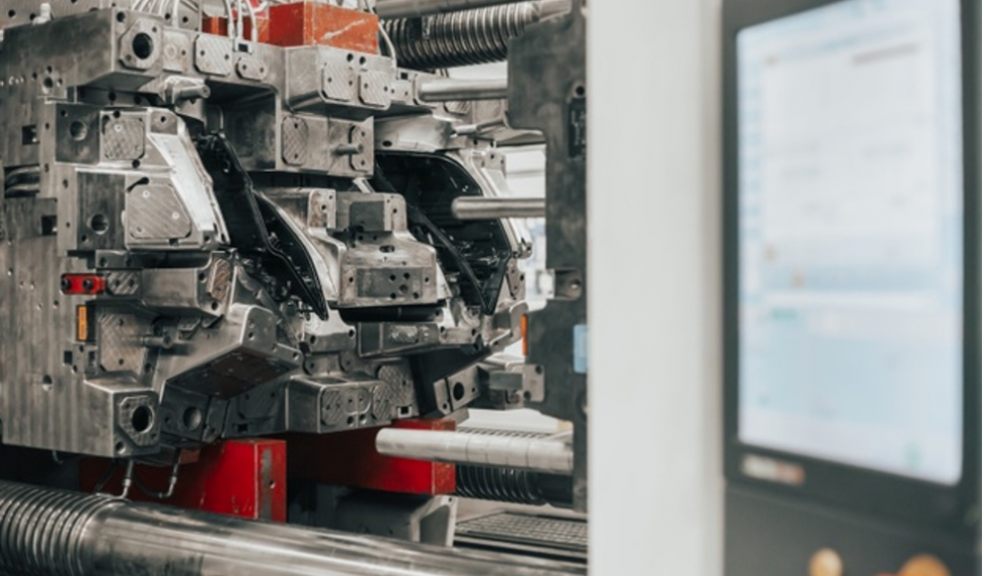

Manufacturers know how essential maintenance and repair are to uphold the safety and efficiency of their facility. With all of the high-power and high-cost machines working in harmony to create products, a simple error such as not cleaning a machine thoroughly can throw off the entire production process. Manufacturers that use injection molding know this fact all too well, as they are consistently ordering purging compounds for plastics to clean their machines thoroughly.

If your faculty does not regularly use a purging compound for plastic build-up and residue to clean your injection molding machines, it would be wise to invest in that practice. The risks of not performing routine maintenance are too great.

Routine Maintenance

Injection molding machines work for hours on end to create plastic parts and components in bulk. Manufacturers need to be sure that their injection molding machines are running properly when they make production plans, as any issues with an injection molding machine could cause a halt to the production process. Checking to make sure that the machine is running properly is only half of the equation.

The other half of the equation is proper cleaning. Purging compounds for plastics can be run through an injection molding machine to clean out any leftover residue or dried plastic bit clogging the machine. It is much easier to clean the machine with a purging compound for plastic when there is a little build-up; otherwise, disassembly and manual cleaning may be required. This reality highlights the need to build cleaning in a routine maintenance procedure.

Limit Risk

Suppose a plastic injection molding machine is not regularly cleaned with a purging compound for plastics during a routine maintenance schedule. Simple oversight like this could cause the machine to act irregularly, albeit only slightly and undetectably. The machine churns out its set number of products, and they get sent to a customer. It’s only later that you find out that the product you sent is defective due to improper molding.

This is just one potential scenario that could arise from not cleaning a machine regularly, but it is one that has a high potential of happening. The chain of events that would unfold by sending a customer a full order of defective parts would be long and with many links. Simply put, it is not worth the risk.

Prolong the Machine’s Lifespan

Building in a time to clean an injection molding machine with a purging compound for plastic not only limits a facility’s risk of faulty products it also prolongs the lifespan of a machine. Proper maintenance and repair already include scheduled shutdown times to give the machines a break and preserve their functionality, so it should be simple to introduce cleaning into that schedule as well. Injection molding machines are expensive and delicate, and managers want to know that the manufacturing staff is taking all measures to have the machines functional as long as possible.

If Nordell, one of the largest injection moulding manufacturers in the region, recommends using purging compounds for plastics during routine maintenance procedures to ensure efficient and safe operations of their machines, it would be wise for other manufacturers to follow suit.