How Wire Stripping Machines Boost Productivity in Industrial Settings

Introduction

In today's fast-paced industrial environments, maintaining productivity and efficiency is crucial for staying competitive. Every aspect of the production process must be optimized, from assembly lines to material handling. One often-overlooked but essential piece of equipment in this optimization is the wire stripping machine. These machines are transforming industries by streamlining wire preparation processes, enhancing precision, and reducing labor costs. In this article, we explore how wire stripping machines play a critical role in boosting productivity across various industrial sectors.

Understanding Wire Stripping Machines

Wire stripping machines are devices designed to remove the insulation from electrical wires, allowing the exposed metal underneath to be used for further processing or assembly. They are primarily used in industries that require large-scale wiring work, such as electronics, automotive, and manufacturing. There are different types of wire stripping machines, each catering to specific needs:

Manual Wire Stripping Machines: Typically used for smaller batches or specialized wire types, these machines are operated by hand and require the operator's input for each wire.

Automatic Wire Stripping Machines: Designed for high-volume applications, automatic machines can strip wires of various sizes and materials with minimal human intervention.

Specialty Wire Stripping Machines: These are customized for specific industries or wire types, offering advanced features like adjustable stripping lengths and multi-functional capabilities.

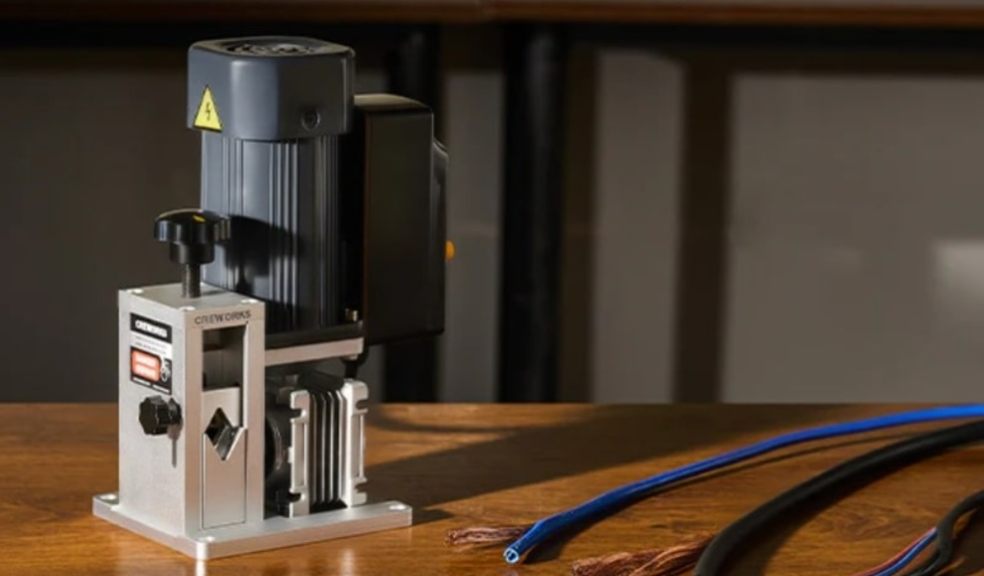

Wire stripping machines are indispensable for industries where precision and speed are paramount. Some manufacturers, like Creworks, offer machines that are designed for industrial environments, providing a balance between affordability and durability.

Key Benefits of Wire Stripping Machines

Enhanced Efficiency

Wire stripping machines significantly increase the speed of wire preparation. Automated systems, in particular, can strip hundreds or even thousands of wires per hour, far surpassing manual methods in both speed and consistency. This reduces downtime and speeds up the entire production process.

Cost-Effectiveness

By automating the wire stripping process, companies can reduce their labor costs. Fewer workers are needed for wire preparation tasks, allowing labor to be allocated to more complex or value-adding activities. Additionally, machines are often designed for longevity, offering low maintenance costs over time.

Improved Precision

Unlike manual stripping, which can lead to inconsistent results or damaged wires, wire stripping machines provide uniform results. This precision is crucial in industries like electronics and automotive manufacturing, where the quality of wiring directly affects the final product's performance.

Versatility

Modern wire stripping machines are designed to handle a wide variety of wire types, from delicate electronics cables to thicker, industrial-grade wires. This adaptability is key for industries dealing with a diverse range of products and materials.

Role in Boosting Industrial Productivity

Streamlining Operations

Wire stripping machines are often integrated into larger production lines, where they can work seamlessly with other automated processes. This integration reduces bottlenecks that would occur if wires had to be manually stripped before proceeding to the next phase of production.

Scaling Production

As demand for products increases, the need for more efficient production methods becomes more urgent. Wire stripping machines can scale production to meet these higher demands, providing a steady supply of properly stripped wires without sacrificing quality or increasing labor costs.

Reducing Downtime

Machine reliability is a critical factor in industrial productivity. Wire stripping machines are engineered for long-term use with minimal downtime. Their ability to operate continuously means that industries can maintain consistent output, avoiding delays caused by breakdowns or slow manual processes.

Case Studies and Real-World Examples

Automotive Industry: In the automotive sector, wire stripping machines are integral to the production of wiring harnesses, which are used extensively in car assembly. These machines ensure that wires are stripped accurately and quickly, keeping up with the high-speed pace of automotive manufacturing.

Electronics Manufacturing: In PCB production, wire stripping machines are used to strip wires with high precision, ensuring that components fit correctly and function as intended. This is particularly important in consumer electronics, where quality control is essential.

Recycling Industry: Wire stripping machines are also invaluable in the recycling sector, where they help to efficiently strip insulation from copper wires. This process not only recycles valuable materials but also saves labor costs and boosts processing speeds in scrap recycling.

Factors to Consider When Choosing a Wire Stripping Machine

Production Needs: The volume of wire processing and the types of wires being used should guide the selection of a wire stripping machine. Industries with high production demands will benefit from automatic machines, while smaller operations may opt for manual models.

Machine Features: Features such as adjustable stripping lengths, easy-to-use interfaces, and the ability to handle a variety of wire types are important considerations. Machines with user-friendly settings and minimal maintenance requirements can contribute to long-term productivity gains.

Budget Constraints: While the upfront cost of wire stripping machines can vary, it's important to weigh the initial investment against the potential savings in labor and the benefits of faster, more precise stripping. Over time, the ROI from increased efficiency and reduced errors often justifies the cost.

Durability and Maintenance: Machines that require frequent repairs or are prone to breakdowns can disrupt production. Investing in a reliable and durable wire stripping machine can ensure consistent performance over time.

Conclusion

Wire stripping machines play a vital role in enhancing productivity in industrial settings by offering speed, precision, and cost-efficiency. By automating the wire preparation process, businesses can reduce labor costs, improve product quality, and streamline their operations. The right wire stripping machine, whether a basic manual model or a high-tech automatic machine, can significantly contribute to a company’s overall productivity. Industries that embrace these tools will find themselves better equipped to meet the demands of modern manufacturing.

By understanding the advantages these machines offer, businesses can make informed decisions on the best equipment for their needs, ensuring long-term success and competitiveness.