How to select the perfect electronic manufacturing services partner

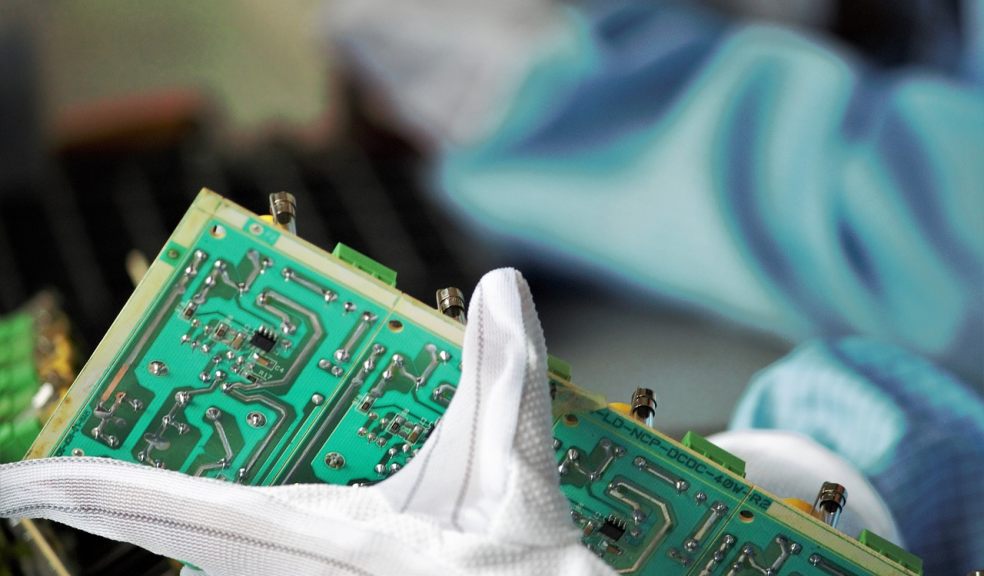

Outsourcing has become a very integral part of every company project across different industries. Likewise, electronics manufacturing services (EMS) that design, manufacture, distribute and repair electronic components for original equipment manufacturers (OEMs) is also becoming more and more prevalent. These companies are an integral part during the circuit board production, assembly of electronic items, and during PCB designs.

With an EMS service being so important, it is vital to develop a productive partnership with a company to reduce cost, reduce installation and production time and increase quality. So, without further ado, let me highlight some important factors to consider when selecting an electronics manufacturing services partner.

Analyze Your Product Range

Every business has some unique product that it capitalizes on. When looking for an electronics partner, you should keep the requirements surrounding that unique product in mind and contemplate how acquiring an EMS will help you increase its production.

Look at what you can do well, which parts you can manufacture yourself and which processes should be outsourced. A good manufacturing service like mjsdesigns.com reduces the cost of production when compared to manufacturing that item on your own and improves the quality of production as well.

Ask for References

Outsourcing EMS is a critical decision, and in order to make sure that the service you are choosing is as excellent as it is advertised, you should ask around about it. References always offer valuable insights into what a service is actually capable of.

Seek references from companies that manufacture products similar to yours and are outsourcing the same processes that you want to outsource.

Does the ESM Integrate with Your Company?

When you browse the market, you will find that there are several ESM partners, and each of them is claiming to provide different services. Instead of going for a partner that provides everything in the market, you should select a partner who is the most compatible with your company. By analyzing the core production processes, product line and assemblies, you should be able to determine how well a partner’s process will integrate with your own. By browsing over to electro mechanical assembly, you can compare services provided by them and the services you want to outsource.

Do a Background Check

Background checks are one of the most essential steps for choosing a partner. The last thing you will want is getting into business with a shady company. Pick a company with strong financials to ensure that they will not run away in the middle of the project.

Take a look at their distributors and ensure that they are investing in modern equipment and technology to make products of the top-most quality.

Trust Your Instincts

After conducting your research, just go with your instinct. You would have learnt a lot about a company by engaging in a conversation with their staff and officials. If they sound enthusiastic about working with you and seem interested in taking your products to the next level, you will have a good feeling about them.

If a company doesn’t care much about customer relation or how it projects itself to external visitors, it’s better not to rely on them to meet your needs.